Homeowners can get a rough idea about the cost of their kitchen remodelling with the help of this Worktop Cost Calculator. This general price investigation method is made using the pricing information from various kitchen companies across the UK. It is to be noted that this is only an approximate budget planner for the homeowners and the actual price shall vary depending on various factors like material, personalised requirements and the fabricator they choose to work with.

We would like to recommend you to visit our collection to select your stones and check prices before you start calculating the price for your worktop.

Price Per Square Meter

Length and Width

Total Square Meter: 0.00

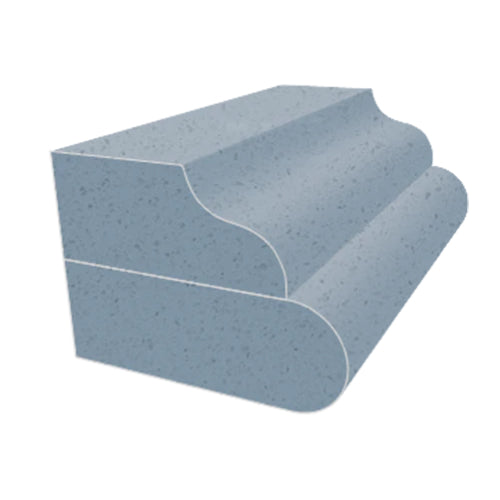

Edge Type

Edge Type Reference

Single Arris

Single Arris

Double Arris

Double Arris

Single Radius

Single Radius

Double Radius

Double Radius

Mitred Arris

Mitred Arris

Mitred Radius

Mitred Radius

Rolled

Rolled

Dupont

Dupont

Demi Bullnose

Demi Bullnose

Half Bullnose

Half Bullnose

Full Bullnose

Full Bullnose

Ogee Bullnose

Ogee Bullnose

Sharknose Standard

Sharknose Standard

Sharknose Square

Sharknose Square

Inverted Sharknose

Inverted Sharknose

Double Full Bullnose

Double Full Bullnose

Countertop Cost: £0.00

Note:

- If you are looking for an L-shaped worktop or a peninsula kitchen please split the worktop into two or three parts accordingly to enter the dimensions.

- The price displayed by the calculator doesn’t include templating & Installation costs, therefore that shall be added when we provide the quotation(The average cost for templating between £300.00 to £550.00 and the average cost for Installation between £1200.00 to £4000.00)

Image Reference

Worktops

Island

Upstand

Splashback

Window Cills

Overhang

Waterfall Edge

Drainer Grooves

Tap Cutouts

Sink Cutouts

Hob Cutout

Curved Round Corner